AX/SA Series

The Axial Fans, used especially in the refrigeration sector, are suitable for use when reduced space is required with high air volumes and medium-low pressure.

15 – 54 W

0,13 – 0,40 A

90 – 900 m3/h

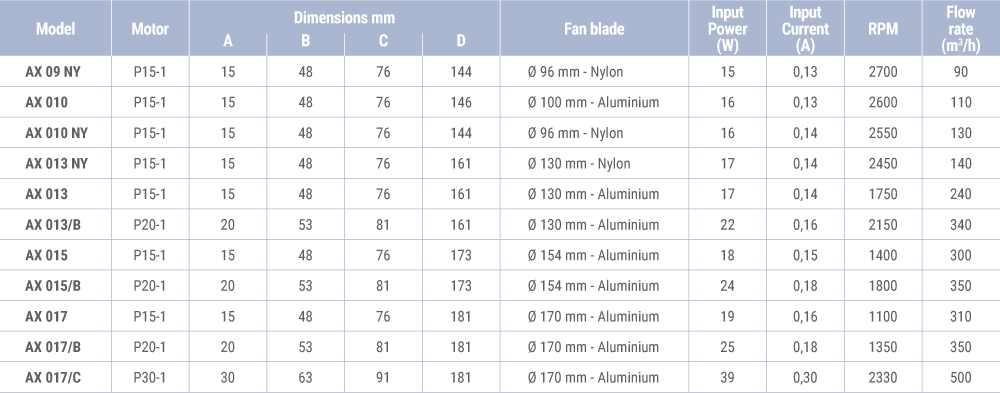

Technical specifications

-

Single phase, 2-shaded poles, impedance protected motor, built according to the CE mark requirements, in compliance with EN 60335-1 standard, with self-aligning and self lubricating sleeve bearings with big oil reservoir.

-

Motor with minimum 130° “B” insulation class.

-

Suitable for continuous operation in ambient temperature from -10 °C to +50 °C.

-

Electrical connection by 6,3 x 0,8 mm, radial or axial, male faston-type connectors, directly fixed on coil.

-

Fan blade made of nylon reinforced with fibreglass or aluminium.

-

Motor support bracket made of galvanized metal sheet.

On request

-

Version with IMQ – CSV approved motor.

-

Motor with different powers and insulation classes: 155° “F” – 180° “H”.

-

Supply voltage from 12V to 400V 50/60 Hz.

-

Version with dual voltage and/or double speed.

-

Electrical connection by different cable lengths.

-

Motor coil winding with IP55 protection.

-

Protection against dust and/or humidity.

-

Thermal protector or thermal fuse.

-

Built in compliance with UL – CSA standards.

-

Fans blades of various diameters and inclinations.

-

Without the support bracket.

-

Spacers of various lengths and/or protruding screws for fan wall mounting.

-

Motor cover made of black nylon reinforced with fibreglass.

-

SA type bracket for use with fan blades 200 mm and 230 mm diameter.

-

Version fitted with ball bearings.

-

Version built to customers design

Faston position and rotation

Fan blade action

Blowing

The overall dimensions of the motor reduce fan performance

Suction

We recommend the suction version

Product Identification Code

| AX | AX or SA series. |

| 017/B | Model. |

| T | Thermal protection: T = thermal protector. F = thermal fuse. Blank = impedance protected. |

| 1 | Coil winding code. |

| 3 | Faston position. |

| R | Electrical connection: R = radial faston-type connectors. A = axial faston-type connectors. C = cables. |

| A | Rotation: O = clockwise. A = anticlockwise. |

| A | Action: A = suction. P = blowing. |

| IV | On request: HT = high-temperature version. IV - IM = low temperature with high humidity up to 92%.* INC = coil insulation with IP55 protection. * |

| 230 | Supply voltage. |

| 50 | Rated frequency. |

* IV version

Impregnated coil through dip-coating using epoxy transparent paint (standard stator coil dip-coating process).

* IM version

Impregnated coil through dip-coating using transparent epoxy paint with silicone applied on contacts at the end of winding, three-pole wire and coil covered by a nylon cap. The coil is not drowned in the resin but visible; caution should be paid when mounting the motor so that the cap open part faces downward to prevent its filling up with condensate.

* INC version

Coil with IP55 protection, the coil is completely drowned into the epoxy resin.

Dimensions

AX

Dimensions

SA