P Series

Single-phase 2 shaded poles Motors for various applications.

These motors are extremely cheap and strong, with an irreversible rotation direction; they do not produce radio interference.

14 – 48 W

0,12 – 0,36 A

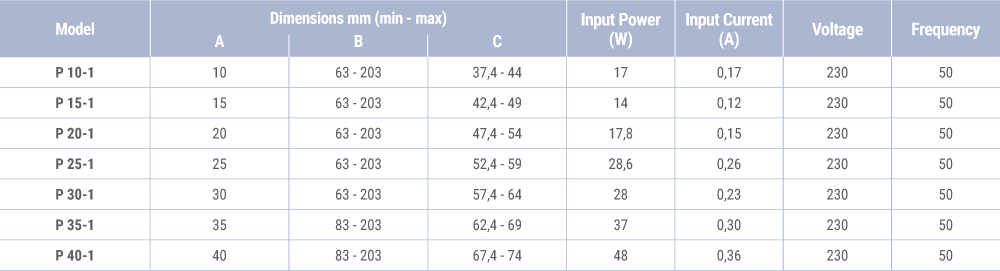

Technical specifications

-

Single phase, 2-shaded poles, impedance protected motor, built according to the CE mark requirements, in compliance with EN 60335-1 standard, with self-aligning and self lubricating sleeve bearings with big oil reservoir.

-

Motor with minimum 130° “B” insulation class.

-

Suitable for continuous operation in ambient temperature from -10 °C to +50 °C.

-

Electrical connection by 6,3 x 0,8 mm, radial or axial, male faston-type connectors, directly fixed on coil.

-

61 x 61 mm stator lamination.

-

4,5 mm or 6 mm diameter driving shafts.

On request

-

IMQ – CSV approved version.

-

Motor with different powers and insulation classes: 155° “F” – 180° “H”.

-

Supply voltage from 12V to 400V 50/60 Hz.

-

Version with dual voltage and/or double speed.

-

Electrical connection by different cable lengths.

-

Motor coil winding with IP55 protection.

-

Protection against dust and/or humidity.

-

Thermal protector or thermal fuse.

-

Stator with cataphoresis coating.

-

Built in compliance with UL – CSA standards.

-

End-shields with different shapes.

-

Spacers of various lengths and/or protruding screws for motor wall mounting.

-

Cooling fan.

-

61x 64 mm stator lamination (E series), 10 to 40 mm motor stack height, of different powers.

-

Driving shaft built to customers design.

-

Version fitted with ball bearings.

-

Version built to customers design.

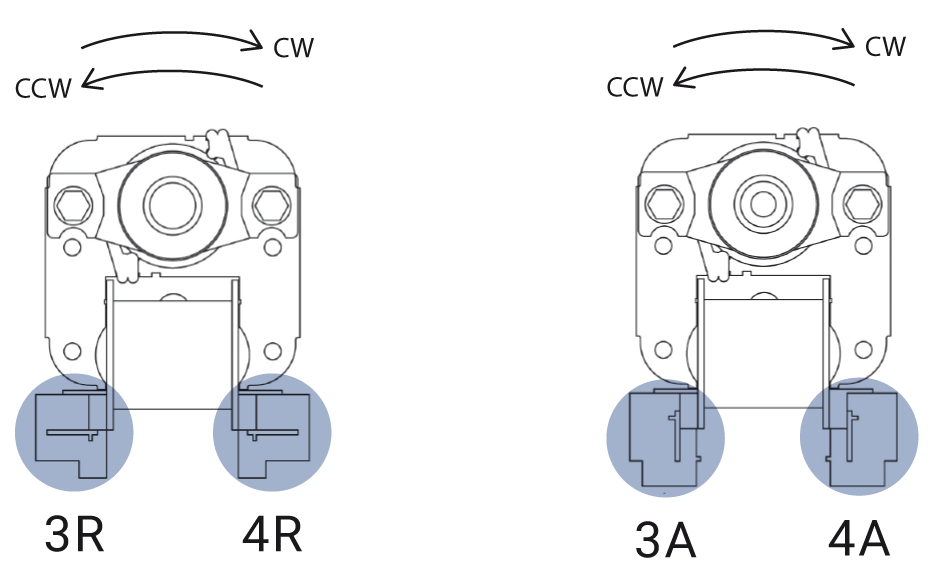

Faston position and rotation

Product Identification Code

| P | Series. |

| 20 | Motor stack height: 10 - 15 - 20 - 25 - 30 - 35 - 40 mm. |

| T | Thermal protection: T = thermal protector. F = thermal fuse. Blank = impedance protected. |

| 1 | Winding code. |

| 3 | Faston position. |

| R | Electrical connection: R = radial faston-type connectors. A = axial faston-type connectors. C = cables. |

| A | Rotation: O = clockwise. A = anticlockwise. |

| BB | On request: BB = ball bearings. |

| IV | On request: HT = high-temperature version. IV - IM = low temperature with high humidity up to 92%. * INC = coil insulation with IP55 protection. * |

| VR | On request: VR = fitted with cooling fan. |

| 230 | Supply voltage. |

| 50 | Rated frequency. |

* IV version

Impregnated coil through dip-coating using epoxy transparent paint (standard stator coil dip-coating process).

* IM version

Impregnated coil through dip-coating using transparent epoxy paint with silicone applied on contacts at the end of winding, three-pole wire and coil covered by a nylon cap. The coil is not drowned in the resin but visible; caution should be paid when mounting the motor so that the cap open part faces downward to prevent its filling up with condensate.

* INC version

Coil with IP55 protection, the coil is completely drowned into the epoxy resin.

Dimensions