BL10

Range

The Brushless motor BL10 was conceived and manufactured to grant an high energy-saving motorization, as an alternative to the classic shaded pole motor, to match all our fans.

Unlike the common brushless motors, our BL10 behaves similarly to shaded pole motors. Assembled with our fans, it offers an air flow that varies thanks to the pressure drop in the application.

Advantages

The BL10 brushless motor boasts almost all the technical features of other motors granting:

- About 80% energy-saving as compared to shaded pole motors.

- The use of a unique motor size

- A huge efficiency improvement

- About 70% performance

Functionality

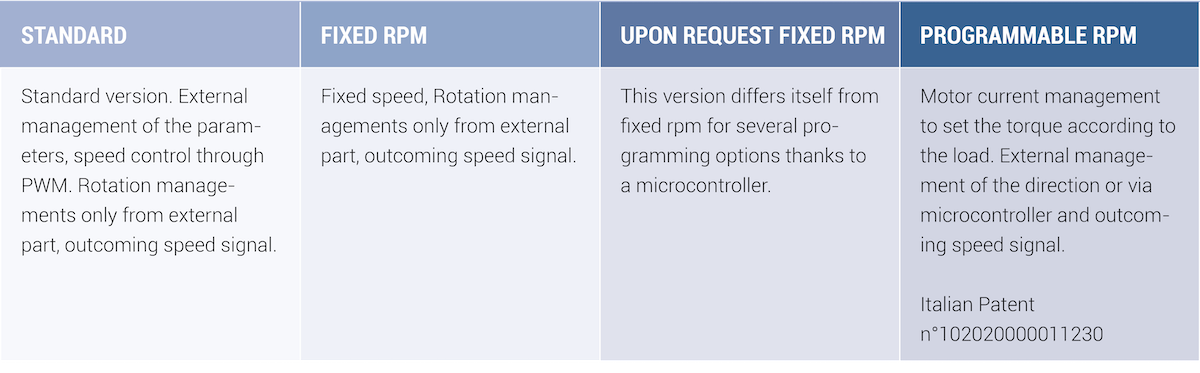

Coprel conceived 4 different drive versions (electronic boards) for the brushless motor control, that differ for their functionalities:

PROGRAMMABLE RPM

This patented activation allows the substitution of the classic shaded pole motor fan without the implementation of an external control device, just an electrical connection needed. Starting from Standard version until the Programmable rpm version the motor independence level increases reducing in the meantime the inlet parameters required.

Cross-flow Fans

Limited space, high air volume, low noise, regular air flow, a high performance and reliability product series.

Centrifugal Blowers

Designed for conditioning, heating, refrigeration applications where high static pressures are required combined with high yields and also where good air flow levels, static pressure and low noise level are required.

Axial Fans

Used especially in the refrigeration sector, are suitable for use when reduced space is required with high air volumes and medium-low pressure.

Motors

These motors are extremely cheap and strong, with an irreversible rotation direction; they do not produce radio interference.

Gear Motors

Designed and manufactured in Italy using Italian components, are suitable for industrial and professional use in various application.

Stirrers

Designed for stirring low-density liquids, the very low noise and the completely insulated coil ensure optimal operation. The stirrer can be combined with submersible centrifugal pumps.

Motors, Fans and Stirrers for different applications

All Coprel products are manufactured in its Milan factory